News

Maintenance tips for BOP

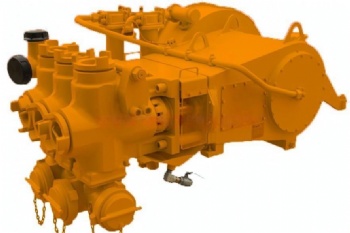

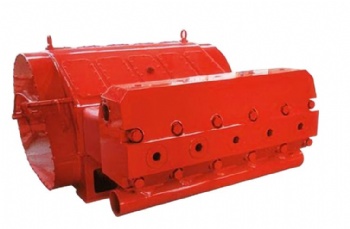

The management and maintenance of BOPs is important for oil companies. BOPs are related to whether oil companies can work normally. For the management and maintenance of these equipment, the actual characteristics of oil companies must be considered, and at the same time Implement relevant management standards. Below, I will briefly introduce the maintenance and maintenance measures of the blowout preventer.

1. In daily maintenance, pay attention to keeping the face of the blowout preventer dry. These devices cause wear and tear during normal use. At the same time, observe the bearing equipment and friction parts of the equipment, as well as the temperature of the gear box and hydraulic oil tank. In the case of lifting, the temperature of each part should not be higher than 70 ℃. Once the temperature is higher than this, the equipment must be shut down to reduce the temperature, and the cause of this problem should be found in time. In addition, in the daily use of mechanical equipment , Pay attention to listening to the abnormal sounds of the equipment during operation.Once there are some abnormal sounds, most of them are problems with the equipment, they must be shut down for inspection and maintenance.

2. Regularly check the sealing of the blowout preventer. Once it is found that there is an oil leakage at the seal of the equipment, it should be shut down in time and the oil leakage should be sealed. In addition, the connection firmware of each connection should be checked regularly. If it is loose, it should be reinforced in time.

3. Regularly check the performance of the hoses. After working for a period of time, these hoses will crack and pack up. When this happens, replace these hoses in time and check the oil in the fuel tank frequently. If the fluid has deteriorated, add hydraulic oil in time. At the same time, check the hydraulic system frequently. When the filter element pointer points to the red area, it proves that the filter element has been blocked, and it should be stopped immediately. Replace the filter element to avoid damage to the oil pump or motor. Replace it in time.

Categories

Contact Us

- +86-17611660323

- info@snpetro-equip.com

- +86-17611660323

- +86-17611660323