News

How to replace the cone bit

After the roller cone bit works downhole for a certain period of time, the blade diameter of the scraper bit becomes smaller, shorter, and dull, the ability to break the rock will become weaker, and the progress will be slower; the roller cone bit will cause erosion and bearing damage, which will cause Inflexible rotation of the cones or jamming of the cones increases the torque, and accidents may occur if the cones are not lifted out in time; diamond drill bits may cause cracks and breaks in the diamond composite sheet on the drill bit due to the inhomogeneity of the formation , Off, also slow down the drilling footage. In order to speed up the drilling speed of the whole well, it is necessary to replace the used drill bit in time, and the drill bit is in the well of a few hundred meters to several thousand meters. How can the driller replace the drill bit?

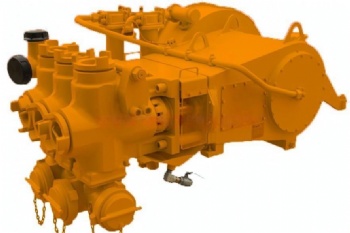

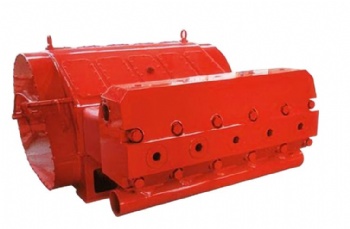

When drilling, the power of the rig drives the turntable, kelly, drill rod and bit to rotate. Observe the working condition of the downhole bit through the instrument on the ground of the rig. After comprehensive judgment, if it is considered that the bit has been worn, it must be stopped and replaced immediately. drill. After stopping drilling, it is necessary to continue to maintain the drilling fluid circulation for a period of time. The purpose is to adjust the performance of the drilling fluid and bring the cuttings suspended in the drilling fluid out of the ground. The circulation keeps the new wall of the wellbore stable, and at the same time Regular inspections of drilling equipment are required. Drilling workers use overhead cranes, traveling blocks and hooks on the derrick to lift all the drilling tools from the well according to the height of the derrick (typically composed of two or three drill rods). After lifting, the drill pipe column is discharged into the derrick in order. When the downhole drill string is raised, the drilling pump is used to continuously inject the drilling fluid into the annular space. The pressure balances the formation pressure to prevent the collapse of the well wall or the fluid in the downhole formation from entering the wellbore. At the same time, special attention should be paid to the sticking that may occur due to the diameter reduction of the well wall, and the operator must strictly control the speed of lifting. After all the drill rods and collars in the wellbore are lifted out, the drill bit to be replaced is also lifted out at the same time. Workers remove the old drill bit and install a new cone bit and then go down the well in the original column order to recover Get into.

Categories

Contact Us

- +86-17611660323

- info@snpetro-equip.com

- +86-17611660323

- +86-17611660323